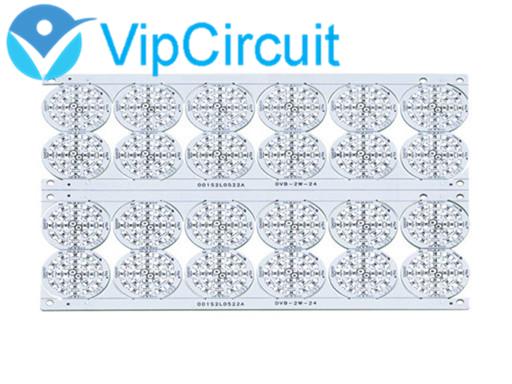

| Name: | Aluminum base PCB |

|---|---|

| Surface finish: | Immersion Gold (ENIG) |

| Finished copper thickness: | 1OZ |

| Material: | Aluminum(1.0W/m.K) |

| Layer: | 1L |

| Finished board thickness: | 1.6mm |

| Min hole size: | 1mm |

| Solder mask color: | White |

| Silkscreen color: | Black |

Product Description

Aluminum base PCB with high thermal conductivity

Excellent thermal performance, mechanical processing performance, electromagnetic shielding performance, dimensional stability, magnetic performance and multi-functional performance,Widely used in hybrid integrated circuits, automobiles, motorcycles, office automation, high-power electrical equipment, power equipment and other fields.

LED PCB board is easy to generate a lot of heat, so it is difficult to cool in traditional way. Therefore, metal core PCB is often selected as LED application because of its enhanced heat dissipation ability. In particular, aluminium is often used to make circuit boards for LED lamps. We have done a lot of research on how to control heat conduction and how to improve the diffuser. If you are an LED manufacturer, or you want to produce some special LED (such as outdoor LED screen), please contact us, we will provide you with the perfect solution of the product. We provide a variety of LED PCB products: high power LED aluminum PCB, metal core PCB, ceramic PCB, FR4 PCB low power LED, high temperature PCB. Aluminum-based PCB has good heat dissipation performance, so it is often used to manufacture high-power LED products.

Aluminum-base material is the indispensable material in its production. It has met the industrial design requirements. It caters to the foreign markets. It is made fine with uses the industry's excellent Bergquist materials, with high thermal conductivity insulation layer. With superior parameters of 500 cycles lasting 350 hours in the range of 40℃~150℃ 2000 hours thermal aging test at 175 ℃ 1 minute at 300 ℃ and 72 hours thermal shock test at 200 ℃, it embodies characteristics such as

In the design of electric circuit, thermal diffusion can be treated effectively.

Reducing the operating temperature of the module, prolonging the service life, increasing the power density and reliability

Reduce the assembly of radiator and other hardware (including thermal interface materials), reduce module size, and reduce hardware and assembly costs

Replacing fragile ceramic substrates for better mechanical durability

It has been proved that aluminum PCB can be applied to communication, medical, military, security, industrial, automotive fields. The strict quality inspection ensures aluminum PCB meets UL, SGS, ROHS, ISO9001,ISO14001,TS16949. We offer this product with customized services.

Vip Circuit is a major manufacturer of rigid, rigid-flex, HDI, any layer, Flex, large-size, embedded, RF, LED, backplane, metal substrate, ceramic substrate, IC structure, high-frequency, heavy copper . Rocket PCB is dedicated to spending 10 years of efforts advancing itself. Industry-leading and years of experience in the aluminum base PCB field.