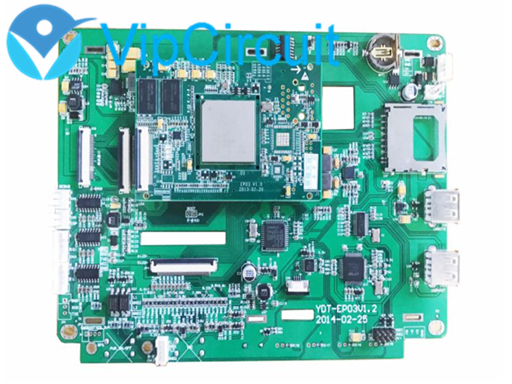

| Name: | Turnkey PCB assembly |

|---|---|

| Name: | Turnkey PCB assembly |

| Description: | Custom electronic circuit board,China PCBA manufacturer |

| Quantity: | Prototype&Low Volume PCB Assembly, from 1 Board to 250,is for specialty, but we can handle orders up to 1000 |

| Type of Assembly: | THD (Thru-Hole Device), SMT (Surface-Mount Technology), SMT & THD mixed, Double-sided SMT and THD assemblyoard to 250,is for specialty, but w |

| Solder Type: | Water Soluble Solder Paste, Leaded and Lead-Free |

| Components: | Passives parts, smallest size 0201; BGA, uBGA, QFN, POP, and Leadless chips; Fine Pitch to 0.8Mils; BGA Repair and Reball; Part Removal and Replacement Connectors and terminals |

| Bare Board Size:: | Smallest: 0.25x0.25 Inches; Largest: 20x20 Inches |

| File Formats: | Bill of Materials Gerber Files Pick-N-Place File(XYRS). |

| Type of Service: | Turn-Key, Partial Turn-Key or Consignment |

| Component Packaging: | Reels,cut tape,Tube and tray,Loose parts and bulk |

| Turn Time: | Same Day Service to 10 day service |

| Testing: | X-ray Inspection AOI (Automated Optical Inspection) ICT (In-Circuit Test)/Functional Testing |

Product Description

PCB Assembly Services – Contract Electronics Manufacturing (CEM)

Detailed Terms for PCB Assembly:

| Technical Requirement | Professional Surface-mounting and Through-hole soldering Technology |

| Various sizes like 1206, 0805, 0603 components SMT technology | |

| ICT(In Circuit Test), FCT(Functional Circuit Test) technology | |

| PCB Assembly With UL, CE, FCC, Rohs Approval | |

| Nitrogen gas reflow soldering technology for SMT | |

| High Standard SMT&Solder Assembly Line | |

| High density interconnected board placement technology capacity | |

| Quote&Production Requirement | Gerber File or PCB File for Bare PCB Board Fabrication |

| BOM(Bill of Material) for Assembly, PNP(Pick and Place file) and Components Position also needed in assembly | |

| To reduce the quote time, please provide us the full part number for each components, Quantity per board also the quantity for orders. | |

| Testing Guide&Function Testing method to ensure the quality to reach nearly 0% scrap rate | |

| OEM/ODM/EMS Services | PCBA, PCB assembly: SMT & PTH & BGA |

| PCBA and enclosure design | |

| Components sourcing and purchasing | |

| Quick prototyping | |

| Plastic injection molding | |

| Metal sheet stamping | |

| Final assembly | |

| Test: AOI, In-Circuit Test (ICT), Functional Test (FCT) | |

| Custom clearance for material importing and product exporting |

Hits: 【Print】

Pre:Flex PCB Next:Small batch pcb assembly