What is the standard thickness of a PCB? What determines the thickness of a PCB?

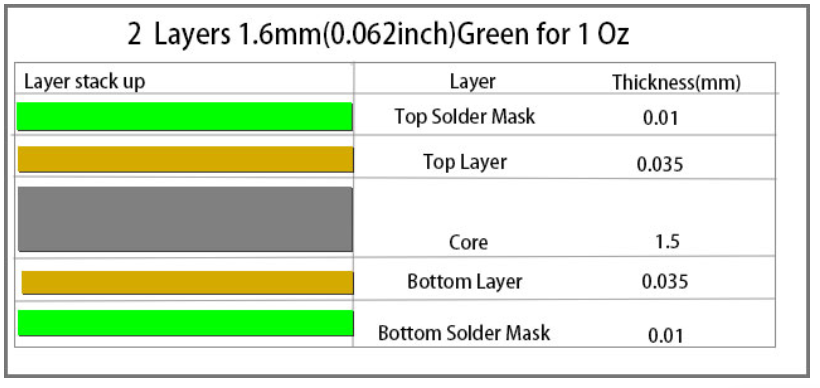

The most common PCB thickness for an FR-4 Printed Circuit Board is 1.57 mm (0.062 inch). This is most the widely used PCB thickness in the industry and is usually the default thickness offered when using the FR-4 substrate.

However, as technology advances and circuits become more complex, the number of layers increases and so does the copper weight. This has resulted in a few more common PCB thickness options that include 93 mils (2.36mm) and 125 mils (3.17mm).

PCB thickness refers to the thickness of the finished Printed Circuit Board. The thickness of the PCB mainly depends on factors such as the number of layers, copper thickness/weight, the substrate used and the operational environment. When discussing the standard PCB thickness, there is no official standard for PCB thickness. But, certain sizes are preferred and have become standard practive among PCB manufacturing companies.

Most PCB manufacturers can fabricate a board with a custom thickness, however, this has its drawbacks and challenges. Most of their equipment is already calibrated to a set of certain fixed thickness options. Using a custom thickness can result in them having to adjust their equipment to fit a specific requirement. This can be done but will result in a higher cost and higher turnaround time.

Design factors that impact PCB thickness:

The following design factors need to be considered during the PCB design phase.

Copper thickness: Copper thickness or copper weight plays an important role in deciding the thickness of a PCB. The thicker the copper layer, the more current it can carry. This thickness needs to be decided based on the required application. The standard thickness of the copper layer is 1.4 to 2.8 mils (1 to 2 oz), but the copper thickness can be adjusted if required. As copper thickness increases, the PCB board thickness also increases.

The required copper thickness depends on the application. For example, a copper trance that needs to carry a high power signal will need to be thicker than one that needs to carry a low power signal.

In most cases, the copper thickness is 1 oz so a PCB manufacturing company will try to adjust the thickness of prepreg and core to try and see if they can meet their target PCB thickness.

Board material: The material selection is one of the factors that decide the PCB thickness. Typically, the board fabrication materials include the material for substrate, laminate, solder mask, and silkscreen. Of these, the substrate and laminate material plays important role in deciding the PCB thickness, as these materials form the board’s structure. Usually, the substrate material is epoxy resin, glass weave, or ceramic, and the laminate material is thermoset resin and either paper or cloth layers. These materials not only decide the PCB thickness; they also decide the thermal, mechanical, and electrical properties of the circuit board.

The number of PCB layers: The number of PCB layers is a major factor that decides the PCB thickness. Based on the application requirement, the number of PCB layers can vary. The higher the number of layers, the thicker the board. A standard PCB with thickness of 1.57 mm (0.062 inch) can have 2 to 6 layers. Anything more than this would result in a thicker printed circuit board. The layer count can to up to 60 layers in some cases, so the board thickness can increase significantly.

Size, weight, and flexibility: Selecting the right PCB thickness for your application depends on several factors. A rigid thin PCB board is usually brittle and can break or crack easily. So, this would not be the right board for use in a rugged environment. A thicker rigid board will be more durable. However, in certain cases, flexible boards are required, the thinner the board the more flexible it is. So this is very subjective and depends on the customer's application.

Manufacturing factors impacted by PCB thickness:

Copper thickness: When a thicker copper layer is used by a PCB the etching process becomes more complicated and can result in the board become more expensive to fabricate.

Depanelization method: The depanelization method is another manufacturing factor that impacts the PCB thickness. Based on the PCB thickness, the fabricator will choose the depanelization method. For example, thicker boards are depanelized by using V-scoring, while the thinner boards are depanelized by using breakaway tabs.

Layer count: When the layer count increases, PCB thickness also increases. The manufacturing of multi-layer boards becomes significantly more challenging.

Factors that need to consider when using a custom PCB thickness:

Usually, PCB manufacturers recommend a set of standard PCB thickness values that they can handle without making any adjustments to their machines. Even though this can be customized, the customer must consider the following points while deciding on a custom PCB thickness:

Know the PCB manufacturer’s equipment capability: It is better to know the PCB manufacturer’s equipment capability; before the PCB design process. It is helpful to avoid the PCB redesign process.

High turnaround time: The customized PCB thickness will need some adjustments to the manufacturing machines. It will increase turnaround time when compared to the standardized PCB thickness.

Additional cost: Yes, some additional costs will need to spend on custom PCB thickness because it may need extra work, material, and manpower than standard thickness PCB.