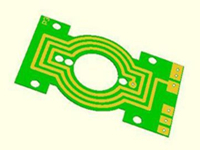

Heavy copper PCB product performance and application

1.What is heavy copper?

When the copper thickness ≥3oz(105μm),we call it

heavy copper.The heavy copper thickness in the actual production and

application usually

are:105μm,140μm,175μm,210μm,245μm,280μm and so on.

2.The function of the heavy copper printed circuit board:

The main source of heat in PCB comes from three aspects: the heat of electronic components, the heat of PCB itself and the other parts beyond PCB such as the heat of the working environment.In the three heat sources,the biggest heat comes from the electronic component calorification,followed by the heat generated of the PCB.The heat of the electronic component is decide by its power dissipation,general speaking,there will be large current more than 100mA through the conducting circuit when the PCB carry a high-power electronic component,so for the large current PCB design,firstly we must to think about that what is the upper limit current does the conducting circuit will bear,then is that what is upper limit heat-resisting capacity of the PCB.Theoretically,the current carrying capacity of copper conductor is proportional to its cross-sectional area.That is, to increase the thickness of the copper foil or increase the line width of the two aspects can be designed to meet the requirements of current load.

3.Optimal design of PCB heat dissipation

If the thickness of the copper foil conducting ability is difficult to meet the requirements of high power PCB safety design, at present, the improvement of PCB heat dissipation ability depends on the wide conductor, thick copper foil, sheet or multilayer structure, large area adding dummy copper or adding copper-based in the PCB, design the heat conduction holes etc. to achieve.